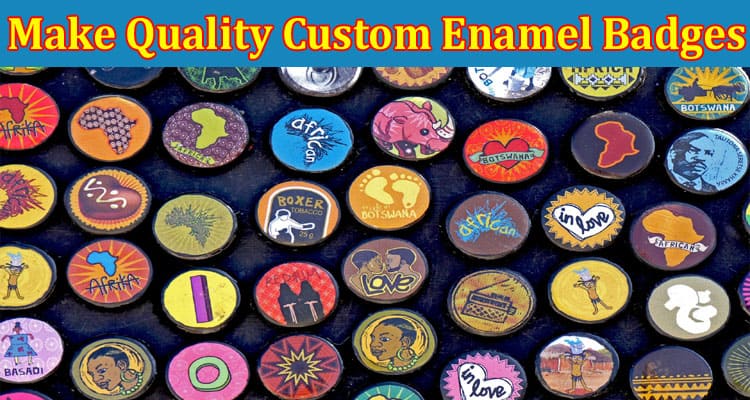

Custom enamel badges can be a good product for promoting your brand or business. Besides that, you can also make custom badges and sell them for a profit. The process of making quality enamel badges is simple.

In this guide, we will share some handy tips on how you can make quality custom enamel badges. You will also find tips on what to consider when looking for a company to mass-produce the pins.

Develop a Design

The first step is to develop designs of how you want your enamel pins to look. You can get inspiration from existing designs. However, don’t copy everything to maintain originality and for your brand to stand out.

On the other hand, you can hire a professional designer. Share ideas on what you want on the pins including your brand colors and fonts. The designer will help add a professional touch to your final design.

The designer will also help you choose the best colors based on design best practices. You don’t want to end up with a design that has too many colors that don’t sync. Too much color or information on the pins will make the design look noisy, and the message you are passing will be lost.

You can get design inspiration from cartoons, superheroes, or custom enamel badges from Rocket Badge.

Different Designs and Shapes

Having a variety of designs and shapes will work best for your brand, especially if you have a wide target audience. Round enamel badges are cool, but having something different will make you stand out. You can create different shapes other than the regular square, rectangle, and circle badges.

Size is also a significant factor, especially if you want to add extra details. At the end of the day, people should be able to read what is on the badge. Small badges may limit your creative space. Having too much on a small badge will also destroy the overall look.

Hard vs. Soft Enamel

Enamel pins are made using enamel paint and metal. The enamel paint is what gives the pins a glossy and smooth finish. Most people like enamel paint because it looks great, is durable once it dries up, and it is strong.

The production process is what separates hard and soft enamel pins. However, soft enamel pins are quite common, and people prefer them because they are more affordable. Hard enamel pins are tougher and more durable than soft enamel pins.

However, one downside of hard enamel pins is that you cannot add too much detail. The complicated manufacturing process also makes hard enamel pins costlier than soft enamel pins.

So, when choosing which type of enamel you want to use, consider your design template. If you have a detailed design, then go for soft enamel. But if you want a smooth finish with less detail, go for hard enamel.

Choosing the Right Metal

When choosing the metal, consider your color palette and design. You have to choose a metal that matches the color of the enamel. All metals are excellent and your choice will depend on your taste.

Soft enamel pins can go with any type of metal finish. Designers can help you choose the right metal and finish that will complement the enamel on your pin. You can also blend in two different finishes on the same type of metal. You can mix brass and gold or silver and brass.

You can make a prototype and get opinions from your clients or employees. The customization options will vary depending on the manufacturer.

Your Budget

How much are you planning to spend? Your budget will decide which type of metal and number of pins you can afford. Always get quotes from different manufacturers to find the best deal that will be worth what you are willing to spend.

Having a budget will also prevent you from overspending. In the end, you don’t want to make too many pins that may end up not getting bought. The best option is to go for 100 first, then order some more whenever necessary.

Also, if you are on a tight budget, make smaller pins. The price of manufacturing each pin will vary depending on the size. Bigger pins with extra detail and a hard enamel finish will be more expensive.

Find a Good Manufacturer

The other thing you should focus on is choosing a good manufacturer. There are some things you need to consider from price to contract terms. Read reviews from other clients before contacting them for their services.

Most manufacturers have a team of in-house designers who can help you design the pins. Besides that, the designers can also fine-tune your prototype and add a professional touch at zero cost. This is always a plus, especially if you are working with a tight budget.

Another thing to consider is the contract terms. Most manufacturers will ask for a deposit fee with the balance being paid after the work is done and you are satisfied with the result. The contract should also include refund terms should the delivery come in late.

Look at some of the past clients and brand the manufacturer has worked with before. You can then get some of their products and review them to see if they meet the quality standards that you are after.

Ask relevant questions such as the minimum order quantity, packaging options, and options available when it comes to materials and shapes.

Wrapping Up

The tips shared in this guide will help you make the best enamel pins for your business. This can also be a good side hustle for creatives who want to share their art with others. You can make custom enamel pins and sell them at events.

Most businesses are shifting towards the use of promotional products for marketing. Custom enamel badges are a good pick since they are cheap to produce. The pins can also be used to target people from different demographics.

Overall, both soft and hard enamel pins are quality choices. Coupled with a good metal finish, you can end up with a masterpiece that will woo your clients.